Backflow Prevention Assemblies

Backflow preventer assemblies are devices designed to prevent the reverse flow of contaminated water into the public water supply system.

They are crucial in maintaining the safety and quality of drinking water. These assemblies consist of various components, including check valves and air gaps, which work together to ensure that water flows in one direction only.

The installation of backflow preventer assemblies is required by local plumbing and fire codes and regulations. They are typically installed in locations where there is a potential for cross-connections between the public water supply and sources of contamination, such as irrigation systems, fire sprinkler systems, or industrial processes. By installing these assemblies, the risk of backflow and the potential contamination of the public water supply are significantly reduced.

Regular testing of backflow preventer assemblies is essential to ensure their proper functioning.

The frequency of testing varies depending on local regulations and the level of risk associated with the specific installation. In general, these assemblies are required to be tested no less than annually, or more frequently if required by local authorities. Testing involves checking the assembly for any leaks, proper operation of check valves, and verifying that the required pressure differentials are maintained. These tests are completed by a licensed backflow tester, using a specific testing tool which simulates backflow while connected to the assembly to verify that pressures hold and don’t drop between check valves.

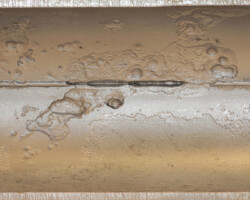

The most common reasons for failure during testing of backflow preventer assemblies include worn-out or damaged components, improper installation, and lack of maintenance. Over time, the internal seals and valves may deteriorate, leading to leaks or backflow. Additionally, if the assembly is not installed correctly or is not properly maintained, it may fail to function as intended. Regular inspections and maintenance are crucial to identify and address any issues promptly, ensuring the continued effectiveness of backflow preventer assemblies.

Contact Columbia Fire today to get a licensed backflow tester or specialty plumber to test your backflow prevention assembly, and provide testing reports to your water and/or fire authority to get you compliant.